100% Natural method

100% Natural method Higher level of safety

Higher level of safety Protection from microorganisms

Protection from microorganisms Guaranteed freshness

Guaranteed freshness More natural products

More natural products Longer shelf life

Longer shelf life

Application of High Pressure Method to meat products

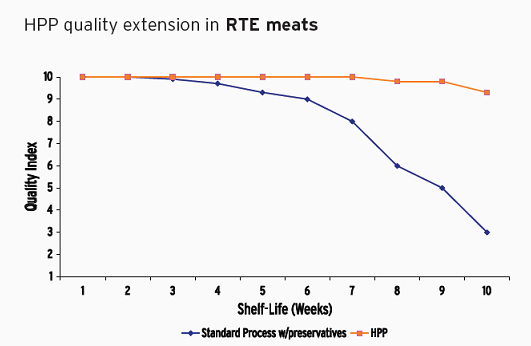

The High Pressure Processing (HPP) method, due to its many and important advantages, finds application to cold cuts and other meat products. It extends the shelf life of products, ensuring high quality while reducing the need for preservatives.

Pathogenic bacteria are destroyed and the microorganisms that cause meat spoilage are significantly reduced. The products retain their organoleptic properties (colour, texture, nutritional value) after High Pressure Processing, throughout their shelf life.

HPP technology can also increase or even double the lifespan of these products.

The High Pressure method is applied after pasteurization or maturing of the product. It is not just a surface treatment, but it works effectively on the whole product, regardless of its size or shape.

This is especially important for sliced cold cuts, where the risk of contamination during packaging with harmful pathogens, especially Listeria monocytogenes, is higher.

Naturally Fresh bring a new era in cold cuts! They use the new HPP (High Pressure Processing) technology, which is a non-thermal process that uses water under extremely high hydrostatic pressure, resulting in the production of packaged foods that are safer, fresher, more natural, tastier and last longer.

✓ 100% Natural method

The HPP method is non thermal, it does not use any radiation nor any chemicals are added. It is a purely natural method.

✓ Higher level of safety

The high pressure of 87,000psi (6000 bar) that is uniformly applied on the products, neutralizes all pathogenic bacteria, such as Listeria, E.Coli and Salmonella without affecting their organoleptic characteristics or nutritional value.

✓ More freshness

The high pressure system inactivates the microorganisms that cause spoilage in food. This preserves the freshness of packaged foods in a natural way, allowing up to doubling their shelf life.

✓ More natural products

The HPP method allows the reduction of added preservatives in food, paving the way for the production of organic and all-natural products.

✓ Improved taste

Foods that are treated with the high pressure method, do not have the harmful effects of exposure to high temperatures, so they retain more of their fresh taste, colour, texture and nutrients.

HPP technology

The High Pressure (HPP) method extends the life of the products by ensuring high quality while reducing the need to add preservatives.

In the last years, more and more consumers have been asking for more natural products with fewer additives, and fresher, as if they had just been produced. But so far, the production of such products, without affecting either their lifespan or their safety, was a big problem.

At the same time, major food safety and health regulators, such as the US Food and Drug Administration (US FDA), the USDA / FSIS, Health Canada and many others, require reliable food safety procedures, detectable and effective. HPP technology comes to meet these needs, satisfying both consumers and regulators, enabling industries to produce products with natural preservatives while minimizing microbiological risks.

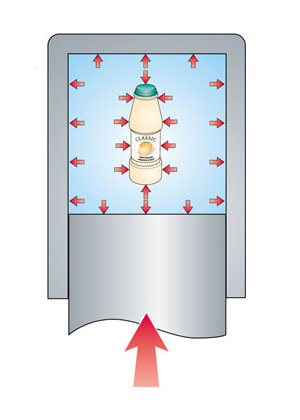

The technology behind the High Pressure Processing system (HPP) is innovative. Using normal cold water at a pressure that goes up to 6000 atmospheres, it neutralizes pathogenic bacteria while preserving the organoleptic characteristics of the products as well as their nutrients. In addition, the microorganisms that cause spoilage in food are significantly reduced. In this way a high degree of protection against dangerous microorganisms is achieved.

The products are placed in special baskets inside a cylinder, which is filled with high-power pumps with water at a pressure of 6000 bar for 3 minutes. The pressure is applied evenly in all places, so even the most sensitive products, such as ham, are not altered.

So now, consumers can enjoy meat products that are more natural, fresher and safer, by choosing Naturally Fresh.

New era in meat products with HPP High Pressure Processing technology!

100% Natural method

100% Natural method Higher level of safety

Higher level of safety Protection from microorganisms

Protection from microorganisms Guaranteed freshness

Guaranteed freshness More natural products

More natural products Longer shelf life

Longer shelf life

Grigoriou meat products are pioneers once again, bringing to Cyprus a revolutionary method, which guarantees the safety and freshness of packaged products, in a completely natural way.

This innovative method does not require extra thermal processing of the product or any chemical treatment. It is based exclusively on the High Pressure (HPP) process, using normal cold water at high pressure, which neutralizes all pathogenic bacteria, such as Listeria, Salmonella, E.coli. In this way, the nutrients and the taste of the products are preserved unchanged, while ensuring a high degree of protection from dangerous microorganisms.

This is how freshness is guaranteed up to the last day.

Naturally Fresh bring a new era in cold cuts and earn an upgraded place in the daily diet, with the confidence of healthy and tasty, confirming that the company is a leader and a pioneer in its field.